Specification:

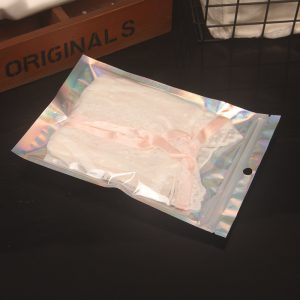

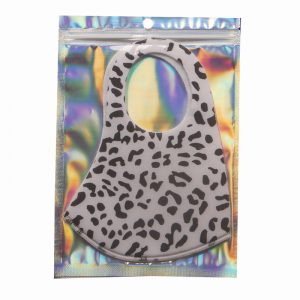

| Item: | Ziplock bag |

| Size/Thickness: | 14*19.8CM、Other Size |

| Design Printing: | Custom Design Gravure Printing |

| Material: | HDPE/LDPE/Biodegradable Plastic(EPI, D2W, Constarch), etc |

| Application: | food.sandwich,popcorn,coffee,biscuit,bread,home,hotels,restaurants,

outdoor,factories, supermarkets |

| Quality Control: | Advanced Equipment and Experienced QC Team will check material, semi-finished and finished products strictly in every step before shipping |

| MOQ: | 1,000pcs |

| Delivery Time: | 10-15 working days after design confirmed. |

| Shipping: | By sea/By air/By Express door to door |

| Payment | T/T, Western Union, Paypal |

| Feature: | Durable and wear-resistant, multi-purpose, factory direct sales, Novel design, reusable |

The production process of ziplock bags

There are two types of zippered ziplock bags. One is direct film blowing. The size above the self-sealing is generally 1.8CM, and the area around the self-sealing is thicker. The left and right sides of the ziplock bag are made into finished products by hot-cutting and sealing. The method of attaching a chain, the latter method is mainly used for the production of composite bags.

The production of self-adhesive ziplock bags is mainly made of single film cross-cutting, heat sealing on both sides, the length of the front and back of the bag is different, one side is 3-5cm longer than the other side, the foldable part, the folded part is pasted with a sticker, which will damage For colloids such as sex glue, tear off the plastic cover on the colloid and fold it back to seal the bag.

The following are the common specifications and sizes of zipper bags. The thickness is generally 0.03mm on one side, also called 3 wires, 3s, and also 0.03mm~0.2mm. Different thicknesses can be produced according to different needs.